Inside a Paint Protection Film Factory: How PPF Is Made

Have you ever wondered how the Paint Protection Film that keeps your car’s paint safe is actually made? This advanced product, also known as PPF or clear bra, goes through a complex manufacturing process before it reaches your vehicle. In this article, we’ll take you inside a paint protection film factory, break down the PPF production process, and explain the technology behind it so you can make smarter decisions when buying and maintaining your car’s protection.

Why PPF Manufacturing Matters

Before investing in automotive paint protection film, it’s important to know what makes a high-quality product. The PPF manufacturing process determines the film’s durability, clarity, and self-healing properties. Poorly made films can yellow, peel, or fail to protect your paint effectively. By understanding how paint protection film is produced, you’ll know what to look for when choosing the right brand. If you’re curious about the different film categories, check out Types of Paint Protection Film for a full breakdown.

The Core Materials Behind PPF

TPU, PVC, and TPH – What’s Inside?

The most commonly used material in paint protection film manufacturing is TPU (Thermoplastic Polyurethane). TPU offers excellent elasticity, self-healing properties, and resistance to chemicals and UV light. Some older films were made from PVC, but they lack flexibility and tend to yellow over time. Premium PPF production processes rely on high-grade TPU for superior clarity and long-lasting protection. To learn more about the composition of these films, visit Paint Protection Film Materials.

Layering Technology Explained

A high-quality car paint protection film manufacturing process involves multiple layers:

- Top Coat: Provides self-healing and stain resistance.

- TPU Base Layer: Adds elasticity and impact absorption.

- Adhesive Layer: Ensures a strong bond with the vehicle’s paint.

This PPF film layering technology is what makes modern films both durable and almost invisible.

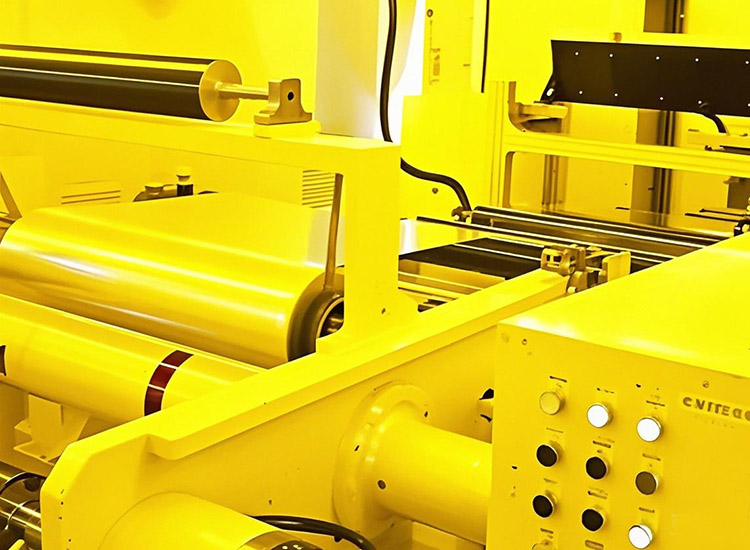

Inside the PPF Factory: Step-by-Step Production Process

Raw Material Selection

It all starts with premium TPU resin. The selection of raw material is critical because impurities can reduce the film’s optical clarity and durability. High-end automotive protective film factories use only certified raw materials for consistent quality.

Film Extrusion and Casting

In this stage, the TPU material is melted and cast into thin, uniform sheets. This process requires advanced machinery to maintain consistent thickness across the entire sheet, which is vital for optimal performance.

Adhesive Application

The adhesive layer is applied using a precision coating system. This is where how PPF adhesive is applied during manufacturing makes a difference—high-quality adhesives provide strong bonding without damaging the car’s paint during removal.

Protective Coating and Self-Healing Layer

A top coat is added to enhance gloss, stain resistance, and self-healing capabilities. This is a key differentiator between basic and premium paint protection wrap production.

Quality Control and Testing

Every roll of film goes through strict paint protection film production quality control. Tests include:

- Optical clarity checks

- Adhesion strength testing

- UV and chemical resistance

- Self-healing performance

Only after passing these tests does the film move to packaging.

Quality Control: Tests Performed During PPF Manufacturing

To ensure every sheet of paint protection film meets premium standards, manufacturers conduct a series of strict quality checks during the PPF production process. These tests guarantee durability, clarity, and long-term performance.

Optical Clarity Test

The film must be nearly invisible once applied. Manufacturers use advanced optical scanners to detect haze, bubbles, or imperfections that can affect transparency.

Adhesion Strength Test

A critical part of paint protection film production quality control is checking adhesive performance. The film should bond firmly to the paint but remain removable without damage.

UV and Weather Resistance Test

High-end PPF is exposed to UV light and simulated weather conditions to ensure it can withstand years of sunlight without yellowing or cracking.

Self-Healing Performance Test

The self-healing layer is tested using heat and friction simulations. This ensures scratches can disappear under mild heat or sunlight, maintaining a flawless look.

Chemical Resistance Test

PPF is subjected to common automotive chemicals such as cleaners, oils, and road salts to verify that the film won’t degrade when exposed to harsh conditions.

Thickness and Elasticity Check

The film’s thickness and flexibility are measured to confirm that it provides impact protection while staying easy to install on complex curves.

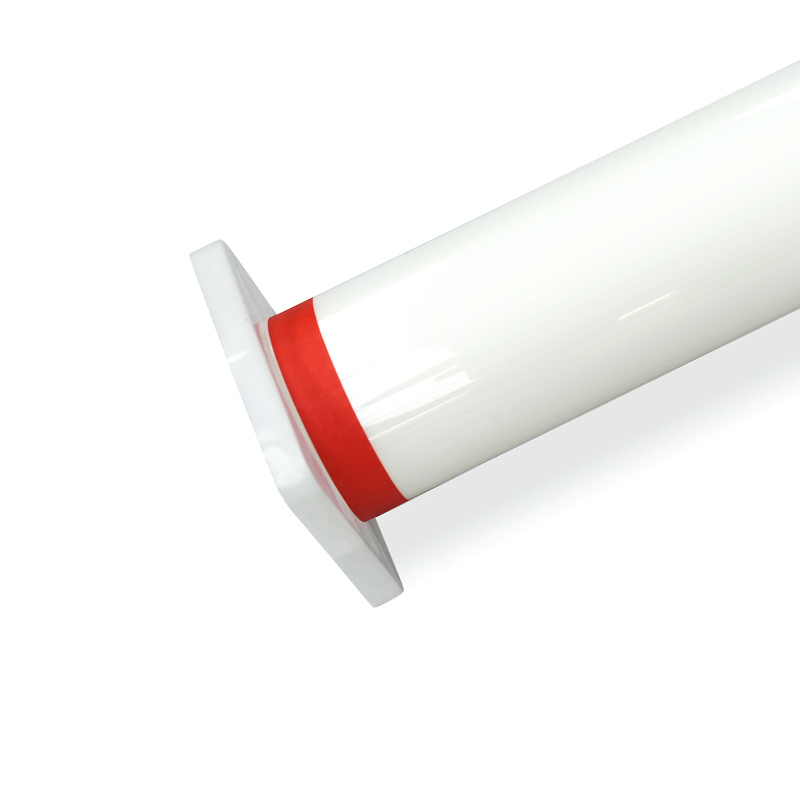

Storage in the Factory: Packaging and Environmental Conditions

Proper storage plays a critical role in maintaining the quality of paint protection film before it reaches customers. Even after the PPF manufacturing process is complete, the film must be handled carefully to preserve its clarity, flexibility, and adhesive performance.

Protective Packaging

After passing all quality control tests, paint protection film rolls are packaged using moisture-proof and dust-proof materials. High-quality packaging prevents contamination, scratches, and exposure to environmental factors during transportation and storage.

Controlled Temperature and Humidity

Inside the automotive protective film factory, storage areas are kept under strict environmental conditions. The temperature is maintained between 15°C and 25°C (59°F–77°F) to prevent adhesive degradation and TPU shrinkage. Humidity levels are also controlled to avoid moisture-related damage.

UV and Light Protection

Exposure to direct sunlight or strong artificial light can cause premature aging of the material. Therefore, PPF factory storage environments are designed to block UV rays and ensure long-term stability of the film before shipment.

Advanced Technology in PPF Manufacturing

Modern PPF factory processes incorporate advanced machinery, including precision extrusion lines, automated adhesive coating systems, and robotic quality checks. These innovations ensure consistent thickness, clarity, and flexibility in every sheet.

How PPF Performance Is Determined by Manufacturing

When customers ask, “What makes high-quality paint protection film?”, the answer often lies in the factory process. A film’s durability, gloss level, and self-healing speed depend on:

- TPU purity

- Coating technology

- Adhesive quality

- Strict quality control measures

If you want to compare options for your car, take a look at Top 12 PPF Brands For Cars for expert recommendations.

Common Myths About PPF Production

Some car owners believe all films are the same, but the difference between premium and low-end paint protection film often comes from manufacturing details. Cheap films may skip key steps like protective coating or use lower-grade TPU, leading to yellowing or peeling. To uncover more misconceptions, read Paint Protection Film Myths and make an informed decision.

How This Knowledge Helps You Choose the Right Film

By understanding how paint protection film is made, you can:

- Compare brands based on material quality and technology.

- Avoid low-quality films that fail prematurely.

- Ensure your investment protects your car for years.

PreproPPF Car PPF PR-Q03

On a budget? Check out basic protection PPF PR-Q01, 5×50 ft, free shipping worldwide.

PreproPPF: Low Price with Free Shipping

At PreproPPF, we specialize in premium paint protection film manufacturing using advanced TPU technology, strict quality control, and eco-friendly processes. Our factory-direct model guarantees competitive pricing and top-quality products. We offer global free doorstep delivery, ensuring customers everywhere can access world-class protection for their vehicles.

Frequently Asked Questions (FAQs)

How Is PPF Manufactured?

PPF is made using TPU or similar materials through an extrusion process, adhesive application, and a protective top coat. It undergoes strict quality control for durability, clarity, and self-healing performance.

Is It Hard To Do Your Own PPF?

Yes, installing paint protection film yourself can be challenging. It requires precise alignment, a clean surface, and professional tools to avoid bubbles and wrinkles. Most people prefer professional installation for the best results.

How Does PPF Look After 5 Years?

High-quality PPF still looks clear and glossy after 5 years if properly maintained. Cheap films, however, may yellow, peel, or lose self-healing ability over time.

What Are The Negatives Of PPF?

PPF can be expensive and requires expert installation. Poor-quality films may discolor or fail, and removing old PPF can sometimes be tricky without professional help.